Surface Mount Technology (SMT): Paving the Way for Compact and Efficient Electronics

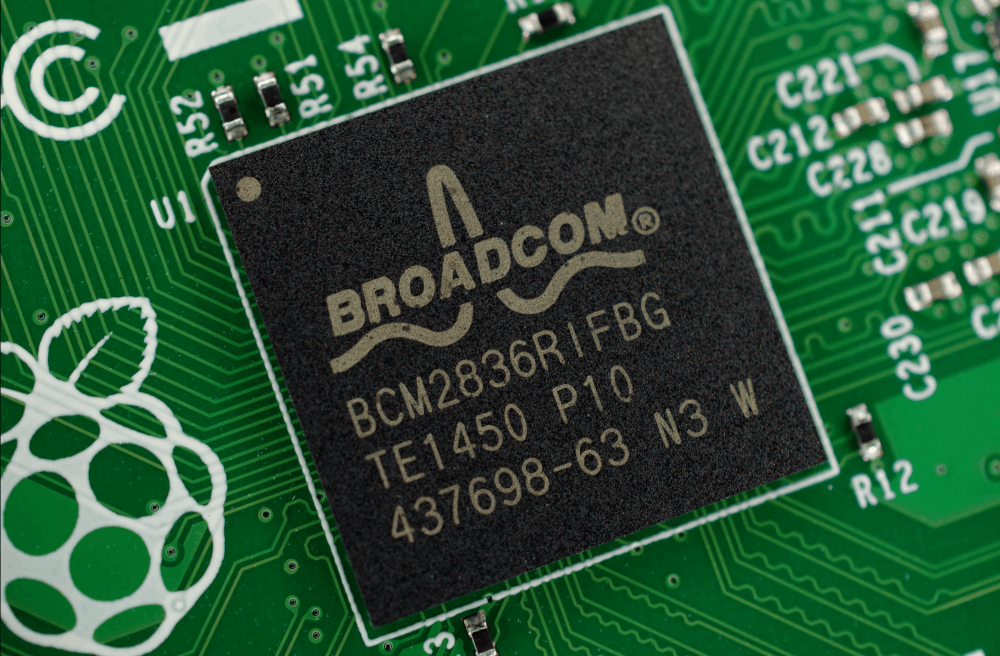

Surface Mount Technology (SMT) has revolutionized electronic assembly, offering a more efficient and compact approach to building electronic circuits. In the realm of electronics manufacturing, SMT has become the go-to method for attaching components directly onto the surface of a printed circuit board (PCB), eliminating the need for traditional through-hole mounting.

One of the key advantages of SMT is its ability to accommodate smaller and lighter components, leading to more compact and sleek electronic devices. This technology allows for higher component density on a PCB, enabling manufacturers to create products that are not only more space-efficient but also more energy-efficient. The reduced size of components contributes to improved performance and enhanced functionality in a variety of electronic applications.

SMT's versatility is another noteworthy aspect. It supports a wide range of component types, including resistors, capacitors, integrated circuits, and other semiconductor devices. This flexibility makes SMT suitable for a diverse array of electronic devices, from smartphones and laptops to medical devices and automotive electronics.

Moreover, SMT facilitates automated assembly processes, significantly reducing production time and costs. Automated SMT assembly lines can handle high-volume manufacturing with precision and consistency, ensuring the reliability of the final product. The increased speed of production also allows manufacturers to keep up with the fast-paced demands of the consumer electronics market.

The evolution of SMT technology has not only improved the efficiency of electronic devices but has also contributed to advancements in miniaturization and portability. As technology continues to progress, SMT plays a crucial role in enabling the development of smaller, lighter, and more powerful electronic gadgets.

In conclusion, Surface Mount Technology has emerged as a cornerstone in the electronics manufacturing industry, driving innovation and enhancing the performance of electronic devices. With its compact design, versatility, and automated assembly capabilities, SMT continues to shape the future of electronic technology, pushing the boundaries of what is possible in the realm of electronics.