Polyfunctional robots

Polyfunctional Robots: The Future of Multifunctional Automation

Introduction

The rapid advancement of robotics and automation technologies has led to the development of increasingly sophisticated robots capable of performing a wide variety of tasks. Among these innovations, polyfunctional robots represent a significant leap forward. These robots are designed to perform multiple functions, often simultaneously, making them more versatile and efficient than traditional single-function robots. Polyfunctional robots combine the power of artificial intelligence (AI), machine learning (ML), and advanced sensors to handle diverse applications across industries such as manufacturing, healthcare, agriculture, logistics, and domestic assistance.

The concept of polyfunctional robots is driven by the need for flexible, adaptive, and multi-purpose automation solutions. By integrating various functionalities, polyfunctional robots can reduce operational costs, increase productivity, and improve overall efficiency in settings that traditionally required multiple specialized machines or human workers. This essay delves into the definition, technological advancements, applications, challenges, and future of polyfunctional robots, providing a comprehensive overview of this revolutionary technology.

What Are Polyfunctional Robots?

Polyfunctional robots are automated systems that can perform a wide range of tasks, often within a single operational framework. Unlike traditional robots, which are typically designed to execute a specific function (e.g., a robot arm for welding in manufacturing), polyfunctional robots are versatile and capable of adapting to different roles. They can be reconfigured, programmed, or equipped with interchangeable tools to perform a variety of functions, making them highly adaptable to dynamic environments.

The primary advantage of polyfunctional robots is their ability to perform multiple tasks within a single system. This multi-tasking capability allows organizations to streamline operations, reduce the need for specialized robots or machines, and lower maintenance costs. For instance, a polyfunctional robot in a warehouse could handle tasks like picking, sorting, packaging, and inventory management, all within the same unit.

Key Characteristics of Polyfunctional Robots:

- Adaptability: These robots can be reprogrammed or reconfigured to perform different tasks based on the needs of the environment or the task at hand.

- Multitasking: Polyfunctional robots can simultaneously or sequentially execute multiple functions, often using advanced sensors and AI-driven decision-making processes.

- Modularity: Many polyfunctional robots feature modular designs, allowing for easy upgrades and the integration of new tools or capabilities.

- Automation: By automating multiple tasks, these robots reduce the need for human intervention and can operate continuously, improving efficiency and productivity.

- AI Integration: Advanced AI and machine learning algorithms enable polyfunctional robots to learn from experience, optimize performance, and adapt to new environments and challenges.

Technological Advancements Enabling Polyfunctional Robots

Polyfunctional robots are the result of significant advancements in several key technological areas. These technologies not only enable the versatility of the robots but also ensure that they can perform complex, multi-faceted tasks with precision and reliability. Some of the core technologies that power polyfunctional robots include:

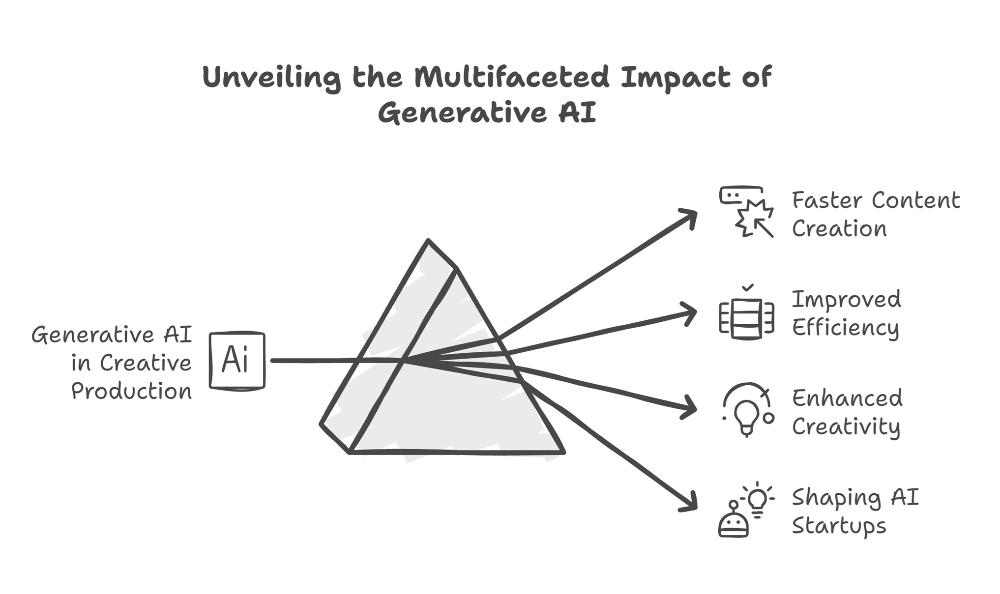

1. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are critical for enabling polyfunctional robots to perform a wide range of tasks. These technologies allow robots to learn from their environment, adapt to new conditions, and make intelligent decisions based on the data they receive. Machine learning algorithms enable polyfunctional robots to improve their performance over time, allowing them to refine their actions and enhance their efficiency.

For example, a polyfunctional robot in a manufacturing plant can learn to identify defects in products by analyzing images or sensor data, and adjust its actions accordingly. AI-powered robots can also optimize their task execution, such as adjusting the speed or precision of a task based on real-time data from their environment.

2. Advanced Sensors and Perception Systems

Polyfunctional robots are equipped with a variety of sensors that help them perceive their environment and interact with it in meaningful ways. These sensors can include cameras, LIDAR (Light Detection and Ranging), infrared sensors, pressure sensors, and tactile sensors. These devices enable robots to gather crucial information about their surroundings, such as the location of objects, obstacles, temperature, or the condition of the environment.

For instance, in autonomous vehicles, LIDAR sensors help the robot navigate and avoid obstacles, while cameras and AI algorithms work together to identify road signs, pedestrians, and other vehicles. The versatility of sensors allows polyfunctional robots to switch between various applications seamlessly.

3. Collaborative Robotics (Cobots)

Collaborative robots, or cobots, are robots designed to work alongside humans in shared environments. These robots are equipped with safety features, such as sensors that detect human presence, and can perform tasks that complement human actions. Polyfunctional robots often integrate cobot capabilities, allowing them to work alongside human operators in environments where safety and efficiency are paramount.

For example, in a warehouse setting, a polyfunctional robot could assist human workers with picking and packing tasks, while ensuring that it does not cause harm to humans through careful movement and proximity sensing. The ability of these robots to adapt to human workflows makes them highly versatile and useful in various industries.

4. Robotic Manipulation and Gripping Systems

A key component of polyfunctional robots is their ability to manipulate objects of varying shapes and sizes. Advanced robotic arms and grippers, such as soft robotic grippers or adaptive hands, provide robots with the dexterity to perform delicate or complex tasks.

Polyfunctional robots equipped with these systems can perform tasks such as assembly, sorting, packaging, and even tasks that require fine motor skills, such as handling fragile objects or conducting medical procedures. These robotic arms can be customized with different tools or attachments, allowing them to perform a wide variety of functions.

5. Cloud Computing and Edge Computing

Cloud computing and edge computing are also important technologies for polyfunctional robots. Cloud computing allows robots to store vast amounts of data and access computing resources remotely, enabling them to perform data-heavy tasks such as machine learning or image processing. Edge computing, on the other hand, allows robots to process data locally, reducing latency and improving real-time decision-making capabilities.

For example, a polyfunctional robot on a factory floor may rely on cloud-based systems to optimize its task execution and learn from data gathered by other robots in the system. At the same time, edge computing ensures that critical decisions can be made in real time without relying on cloud infrastructure.

Applications of Polyfunctional Robots

Polyfunctional robots have a wide array of applications across various industries, thanks to their adaptability and versatility. Some key sectors where these robots are making an impact include:

1. Manufacturing and Industrial Automation

In manufacturing, polyfunctional robots are being used to automate a wide range of tasks that traditionally required multiple machines or human labor. These tasks include assembly, welding, painting, quality control, material handling, and packaging.

Polyfunctional robots can perform several different functions within a single production line, reducing the need for specialized robots or machinery. For example, a robot in an automotive assembly plant might be equipped with different tools that allow it to assemble parts, apply coatings, inspect products for defects, and package finished items, all without requiring human intervention.

2. Healthcare and Surgery

In healthcare, polyfunctional robots are being developed to assist with surgeries, rehabilitation, and patient care. These robots are capable of performing a wide range of medical tasks, such as assisting with surgery, administering medications, and monitoring vital signs.

For example, robotic surgery systems, such as the da Vinci Surgical System, allow surgeons to perform minimally invasive surgeries with high precision. These robots can handle tasks like suturing, incision, and even monitoring the patient’s vitals during the operation.

Additionally, polyfunctional robots can be used in assisted living environments to perform daily tasks such as medication administration, monitoring health conditions, and providing companionship for the elderly.

3. Logistics and Warehousing

Polyfunctional robots are increasingly being deployed in warehouses and logistics operations to streamline the process of inventory management, sorting, packing, and shipping. Robots in these environments can perform tasks such as picking items from shelves, sorting products, packaging shipments, and even loading and unloading goods from trucks.

In addition, autonomous mobile robots (AMRs) are being used in warehouses to navigate autonomously, transporting goods between different areas of the facility. These robots can adjust to different tasks based on the needs of the warehouse, making them highly versatile.

4. Agriculture

In agriculture, polyfunctional robots are being used to automate tasks such as planting, weeding, harvesting, and monitoring crop health. These robots are equipped with sensors and AI algorithms to analyze soil conditions, detect pests, and optimize crop yield.

For example, a polyfunctional robot used for harvesting might be able to cut crops, remove weeds, and analyze soil conditions, all in a single pass through the field. This allows for more efficient use of labor and resources, and can lead to higher crop yields and reduced environmental impact.

5. Domestic and Personal Assistance

At home, polyfunctional robots are being used to assist with daily tasks, such as cleaning, cooking, and providing companionship. These robots can integrate different functions, such as vacuuming, mopping, and even monitoring the home’s security.

Personal assistants, such as robots that help the elderly or individuals with disabilities, are equipped with features like voice recognition, mobility, and the ability to perform tasks like retrieving objects, helping with bathing, and providing emergency assistance.

Challenges of Polyfunctional Robots

While polyfunctional robots offer numerous advantages, there are several challenges that need to be addressed for them to achieve widespread adoption:

1. Cost and Complexity

The development of polyfunctional robots can be expensive, both in terms of initial investment and maintenance. The integration of various functions, advanced sensors, AI, and robotics components requires significant research and development, which increases the cost of production.

For smaller businesses, the cost of deploying polyfunctional robots may be prohibitive, limiting their accessibility. However, as technology advances and economies of scale improve, the cost of these robots is expected to decrease over time.

2. Safety and Reliability

Polyfunctional robots must be safe to operate around humans, especially in shared environments. Ensuring that robots can safely interact with people and other machines without causing harm is a key concern. Developers must implement rigorous safety protocols, including sensors for collision detection, real-time decision-making algorithms, and emergency stop mechanisms.

Additionally, reliability is critical, as robots performing multiple functions must be able to operate continuously and efficiently without breaking down or requiring frequent maintenance.

3. Ethical and Social Implications

As polyfunctional robots become more integrated into industries and households, there are ethical and social concerns related to their impact on the workforce. The automation of jobs previously performed by humans raises questions about employment displacement and the potential for increased inequality.

Furthermore, the privacy concerns associated with robots collecting vast amounts of personal data must be addressed, ensuring that users’ information is protected and that robots are not used for surveillance without consent.

Conclusion

Polyfunctional robots represent the next step in the evolution of automation. By combining multiple capabilities into a single system, these robots offer significant advantages in terms of versatility, efficiency, and cost-effectiveness. They are already being deployed across a wide range of industries, from manufacturing and logistics to healthcare and agriculture, and their potential to transform sectors continues to grow.

While challenges such as cost, safety, and ethical considerations remain, the continued advancement of robotics, AI, and sensor technologies will undoubtedly drive the adoption of polyfunctional robots in the coming years. As these robots become more capable and accessible, they have the potential to revolutionize industries, improve productivity, and enhance the quality of life for individuals and societies as a whole.

![[Honest Review] The 2026 Faucet Redlist: Why I'm Blacklisting Cointiply & Where I’m Moving My BCH](https://cdn.bulbapp.io/frontend/images/4b90c949-f023-424f-9331-42c28b565ab0/1)