Post-COVID Global Supply Chain Shifts

Post-COVID Global Supply Chain Shifts: Navigating a New Era of Trade and Logistics

Introduction

The COVID-19 pandemic triggered an unprecedented global disruption, profoundly affecting economies and industries worldwide. Among the hardest hit was the global supply chain system — a complex, interwoven network of suppliers, manufacturers, distributors, and retailers spanning continents. The crisis exposed vulnerabilities, disrupted production and logistics, and revealed how fragile and interdependent global supply chains truly are.

In the wake of this disruption, companies, governments, and institutions have been forced to rethink supply chain strategies, embrace new technologies, and adopt innovative approaches to build resilience, flexibility, and sustainability. This essay explores the multifaceted shifts in global supply chains caused by the COVID-19 pandemic, analyzing the challenges exposed, strategic adaptations, sector-specific impacts, and the future trajectory of global supply networks.

1. Pre-COVID Global Supply Chain Landscape

Before diving into the shifts, it's important to understand the characteristics of global supply chains before the pandemic.

1.1 Just-In-Time (JIT) Inventory Model

- Globally, companies adopted JIT manufacturing and inventory systems to minimize holding costs.

- This model depended heavily on lean inventories and smooth, predictable flows.

- While efficient in normal conditions, it left little room for disruption or demand spikes.

1.2 Globalization and Outsourcing

- Global supply chains became highly optimized but geographically dispersed.

- Many companies outsourced production to low-cost countries, especially China, to maximize cost efficiency.

- This created complex, long lead-time supply routes vulnerable to geopolitical tensions and logistics disruptions.

1.3 Dependence on Key Nodes

- Certain chokepoints, such as ports, logistics hubs, and semiconductor fabs, became critical nodes.

- Overreliance on specific suppliers or regions created concentration risk.

1.4 Technology Adoption

- Digital supply chain management tools were growing but adoption was uneven.

- Many firms still relied on manual processes or siloed data systems.

2. COVID-19 Pandemic: A Catalyst for Disruption

2.1 Initial Impact on Supply Chains

- Lockdowns and factory closures in China and other manufacturing hubs halted production.

- Demand patterns became unpredictable: sudden drops in sectors like automotive and spikes in healthcare products.

- Shipping delays and port congestions caused severe bottlenecks.

- Labor shortages due to health protocols further hampered operations.

2.2 Supply-Demand Mismatch

- Panic buying and stockpiling by consumers disrupted demand forecasting.

- Imbalances emerged between supply and demand across sectors.

- Scarcity of essential goods like PPE, medical devices, and semiconductors created global shortages.

2.3 Logistics and Transportation Challenges

- Air freight capacity plunged as passenger flights (which carry cargo) were cut.

- Ocean freight saw container shortages and skyrocketing shipping costs.

- Cross-border restrictions and customs delays complicated international trade.

3. Major Shifts in Global Supply Chains Post-COVID

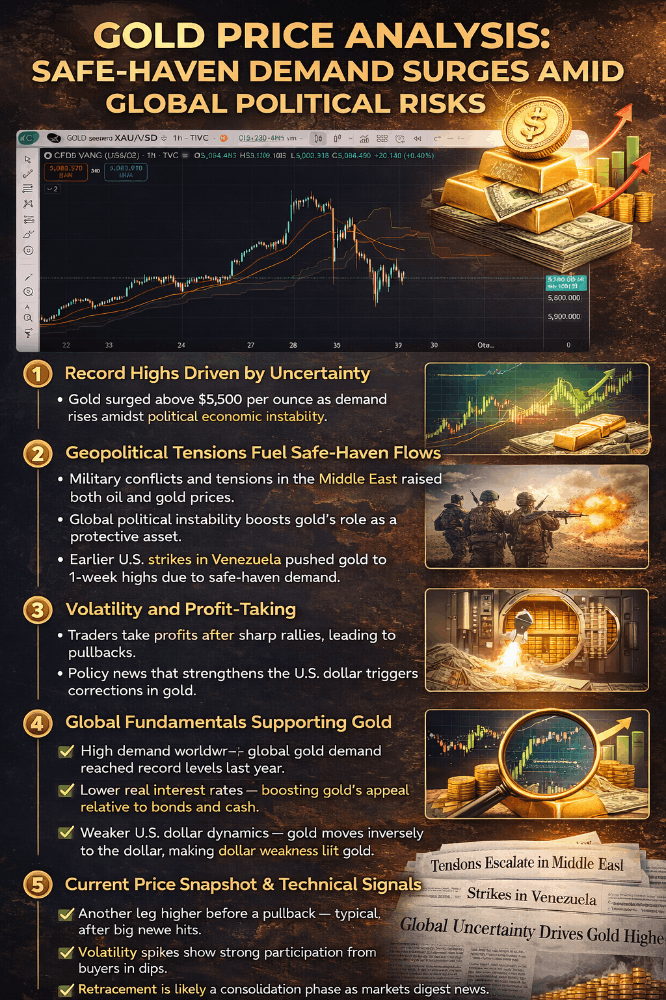

The crisis served as a wake-up call prompting global supply chain stakeholders to rethink strategies. The major shifts include:

3.1 Shift from Efficiency to Resilience

- Prioritizing supply chain robustness over pure cost-efficiency.

- Increasing buffer inventories and safety stock levels to absorb shocks.

- Diversifying supplier base to reduce dependency on single sources or regions.

3.2 Supply Chain Regionalization and Nearshoring

- Moving production closer to end markets to reduce lead times and geopolitical risks.

- Nearshoring and reshoring initiatives gained traction, especially in North America and Europe.

- However, this shift is balanced against higher labor and production costs.

3.3 Enhanced Supply Chain Visibility and Digitization

- Accelerated adoption of digital technologies such as IoT sensors, blockchain, and AI analytics.

- Real-time tracking of inventory, shipments, and demand signals improves responsiveness.

- Cloud platforms enable better collaboration between supply chain partners.

3.4 Emphasis on Sustainability and Ethical Sourcing

- Pandemic highlighted social responsibility, leading to greater focus on sustainable supply chains.

- Pressure to reduce carbon footprints, ensure fair labor practices, and improve transparency.

3.5 Greater Collaboration and Risk Management

- Supply chain risk management frameworks are being revamped.

- Companies engage more deeply with suppliers, logistics providers, and even competitors to build ecosystem resilience.

3.6 Increased Inventory Costs and Strategic Stockpiling

- Stockpiling critical components and raw materials to mitigate future disruptions.

- Companies reconsidered lean inventory models, accepting higher carrying costs as trade-offs.

4. Sector-Specific Supply Chain Impacts and Responses

4.1 Healthcare and Pharmaceuticals

- Demand for vaccines, PPE, and medical devices surged globally.

- Supply shortages led to increased local manufacturing capabilities.

- Cold chain logistics emerged as critical for vaccine distribution.

- Regulatory cooperation improved to accelerate product approvals and distribution.

4.2 Automotive Industry

- Semiconductor shortages severely impacted production.

- Shift towards electric vehicles increased demand for rare earth minerals and batteries.

- Automotive companies diversified suppliers and adopted just-in-case inventory strategies.

4.3 Consumer Electronics

- High demand for laptops, smartphones, and gaming devices during lockdowns strained supply.

- Chip shortages and logistics disruptions caused delays.

- Companies invested in supply chain digitization and alternative sourcing.

4.4 Food and Agriculture

- Panic buying disrupted supply-demand balance.

- Labor shortages in harvesting and processing affected availability.

- Increased focus on local sourcing and shorter supply chains.

4.5 Retail and E-commerce

- Surge in online shopping required agile last-mile delivery solutions.

- Inventory management became critical due to demand volatility.

- Integration of AI-driven demand forecasting and warehouse automation accelerated.

5. Role of Technology in Shaping New Supply Chains

5.1 Artificial Intelligence and Machine Learning

- Predictive analytics for demand forecasting and risk assessment.

- Optimizing inventory and logistics planning.

5.2 Internet of Things (IoT)

- Real-time monitoring of shipments, cold chains, and warehouse conditions.

- Enhanced asset tracking reduces losses and delays.

5.3 Blockchain

- Increasing transparency and traceability.

- Streamlining cross-border trade with smart contracts.

5.4 Robotics and Automation

- Warehouse automation improves efficiency and reduces labor dependency.

- Autonomous vehicles and drones in logistics.

5.5 Cloud Computing and Data Sharing

- Facilitates collaboration across supply chain partners.

- Enables agile response to disruptions.

6. Geopolitical Influences and Trade Policy Changes

6.1 Trade Wars and Protectionism

- Rising protectionist policies post-pandemic added complexity.

- Tariffs and export controls affected sourcing decisions.

6.2 Regional Trade Agreements

- New agreements like RCEP (Regional Comprehensive Economic Partnership) promote regional trade.

- Countries reassess trade dependencies for strategic sectors.

6.3 Government Incentives and Strategic Stockpiling

- Many governments encourage domestic production of critical goods.

- Stockpiling of strategic materials to ensure national security.

7. Challenges in Transitioning to Post-COVID Supply Chains

7.1 Cost vs. Resilience Trade-offs

- Balancing higher costs of diversification and inventory with competitive pricing.

- Smaller companies may struggle to invest in resilience measures.

7.2 Complexity and Coordination

- More diverse supplier networks require sophisticated management.

- Integrating new technologies across legacy systems remains a hurdle.

7.3 Talent and Skill Gaps

- Need for digital skills in supply chain management and data analytics.

- Workforce upskilling and change management critical.

7.4 Environmental and Social Governance (ESG)

- Implementing sustainability without compromising efficiency.

- Meeting rising consumer and regulatory expectations.

8. Case Studies: Companies Adapting to Post-COVID Supply Chains

8.1 Apple Inc.

- Diversified suppliers beyond China, investing in Vietnam and India.

- Increased inventory buffers for critical components.

- Accelerated digital supply chain initiatives.

8.2 Walmart

- Expanded local sourcing and reshaped supplier relationships.

- Leveraged AI and data analytics for demand forecasting.

- Enhanced e-commerce and last-mile delivery capabilities.

8.3 Pfizer

- Developed robust cold chain logistics for COVID-19 vaccine distribution.

- Partnered with logistics firms and governments for rapid global rollout.

9. Future Outlook: Building Supply Chains for the Next Decade

9.1 Hyper-Connected, Agile Supply Chains

- Integration of AI, IoT, and blockchain to create smart, responsive networks.

- Real-time visibility and predictive capabilities to preempt disruptions.

9.2 Focus on Sustainability and Circular Supply Chains

- Reducing waste and carbon emissions.

- Emphasizing recycling and reuse of materials.

9.3 Regional Ecosystems and Collaboration

- Closer collaboration between governments, businesses, and technology providers.

- Development of regional hubs to balance global and local priorities.

9.4 Preparedness for Future Crises

- Scenario planning and dynamic risk management.

- Greater emphasis on supply chain resilience as a strategic priority.

Conclusion

The COVID-19 pandemic irrevocably transformed global supply chains, exposing vulnerabilities while accelerating innovation and strategic shifts. The post-COVID landscape demands a new balance between efficiency and resilience, local agility and global reach, technology adoption and human skills, and economic goals with environmental and social responsibility.

As companies and governments continue to adapt, those who embrace digital transformation, diversify risk, and prioritize sustainability will be best positioned to thrive in an increasingly complex and uncertain global trade environment. The future of global supply chains is one of resilience, collaboration, and innovation — built on the lessons learned from one of the most challenging disruptions in modern history.

If you'd like, I can provide a more detailed breakdown, add charts, or expand any sections!