Deglobalization and Supply Chain Rewiring

Deglobalization and Supply Chain Rewiring: Navigating the New Global Trade Landscape

In recent years, the global trade environment has undergone significant transformations. Factors such as geopolitical tensions, pandemics, and shifting economic policies have prompted a reevaluation of traditional globalization models. This has led to a trend of deglobalization and the rewiring of supply chains, as nations and corporations seek resilience and adaptability in an increasingly uncertain world.

1. Understanding Deglobalization

Definition and Drivers

Deglobalization refers to the process where global interdependencies diminish, leading to reduced cross-border trade, investment, and cultural exchange. Key drivers include:(CEPR)

- Geopolitical Tensions: Trade wars, such as the U.S.-China tariff disputes, have disrupted established trade relationships.

- Pandemic Impacts: COVID-19 exposed vulnerabilities in global supply chains, prompting a shift towards local sourcing.(Vogue Business)

- Nationalistic Policies: Countries are increasingly prioritizing domestic industries and self-sufficiency.(Financial Times)

Implications

Deglobalization doesn't imply a complete halt to global trade but indicates a shift towards regionalization and localized production. This transition affects economies differently, benefiting some while challenging others.

2. The Rewiring of Global Supply Chains

Strategic Shifts

Companies are adopting various strategies to adapt:

- Nearshoring: Relocating production closer to the end consumer to reduce transportation risks and costs.

- Friendshoring: Sourcing from countries with shared values and stable political relations to ensure reliability.

- Diversification: Avoiding over-reliance on a single supplier or region by spreading operations across multiple locations.

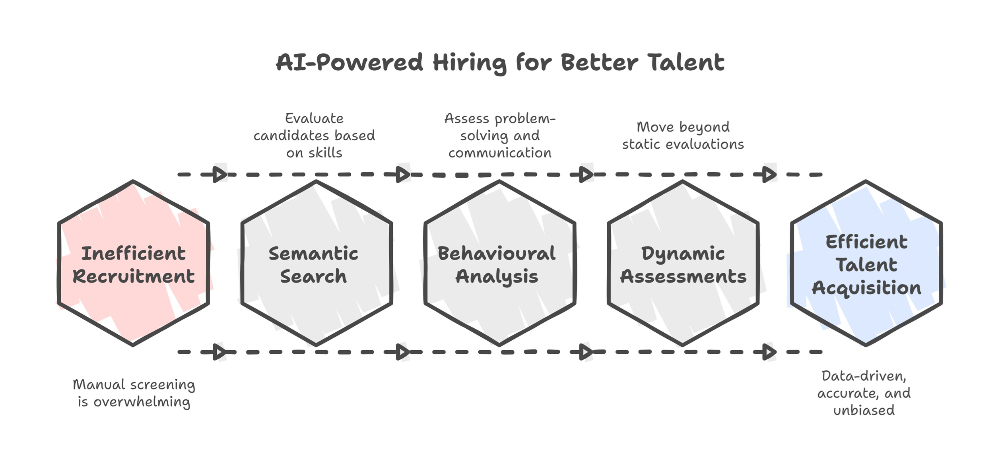

Technological Integration

Advanced technologies like AI and IoT are being leveraged to enhance supply chain visibility and responsiveness. These tools assist in predictive analytics, real-time monitoring, and efficient resource allocation.

3. Sector-Specific Impacts

Manufacturing

The manufacturing sector is witnessing a shift towards automation and localized production to mitigate risks associated with global disruptions.

Retail

Retailers are reconfiguring their supply chains to ensure product availability, often by sourcing from multiple regions and investing in local warehouses.

Technology

Tech companies are diversifying their component suppliers and investing in domestic semiconductor manufacturing to reduce dependency on specific countries.

4. Challenges and Opportunities

Challenges

- Increased Costs: Transitioning to new supply chain models can be capital-intensive.

- Complex Coordination: Managing a diversified supply chain requires sophisticated logistics and communication.

Opportunities

- Resilience: Diversified supply chains are better equipped to handle disruptions.

- Local Economic Growth: Nearshoring and localized production can boost domestic employment and economies.

5. Future Outlook

The trend towards deglobalization and supply chain rewiring is expected to continue, influenced by ongoing geopolitical developments and technological advancements. Companies that proactively adapt to these changes, embracing flexibility and innovation, will be better positioned to thrive in the evolving global trade landscape.

Note: This overview provides a condensed analysis of the complex dynamics of deglobalization and supply chain restructuring. For a more detailed exploration, further research and sector-specific studies are recommended.