Single Wall vs Double Wall Corrugated Boxes | Which Is Better?

When it comes to packaging and shipping, choosing the right type of box matters a lot. Whether you are running a business or simply shipping something to a friend, the kind of box you use can affect the safety of your items, shipping cost, and overall satisfaction. Two of the most commonly used types of boxes are single wall and double wall corrugated boxes. At first glance, they might look the same. But they are built differently and serve different purposes.

In this article, we will explain what these boxes are, how they differ, and which one might be better for your needs. We will keep the language simple so anyone can understand, even if they have no background in packaging.

What Are Corrugated Boxes?

Let’s start with the basics. A corrugated box is made up of layers of paper. These layers include:

- Outer liner – The outside surface of the box.

- Inner liner – The surface inside the box.

- Fluting – A wavy layer of paper between the liners that adds strength.

This fluted paper layer is what gives corrugated boxes their strength and cushioning ability. The number of fluted layers determines if the box is single wall, double wall, or even triple wall.

What Is a Single Wall Corrugated Box?

A single wall box is the most common type. It has one layer of fluting between two liners. So, if you were to cut the box and look at its edge, you would see three layers: one fluted middle layer and two flat liners.

Structure:

- Liner

- Flute

- Liner

Best for:

- Lightweight items

- Everyday shipping

- Standard packaging needs

Common uses:

- E-commerce parcels

- Food packaging

- Office supplies

- Clothing

Single wall boxes are ideal for items that do not require heavy protection. They are lighter and more affordable compared to double wall boxes.

What Is a Double Wall Corrugated Box?

A double wall box has two layers of fluting and three liners. This makes it stronger and more rigid. It offers better protection against impacts and can carry heavier or fragile items.

Structure:

- Liner

- Flute

- Liner

- Flute

- Liner

Best for:

- Heavier or fragile items

- Long-distance shipping

- Storage over long periods

Common uses:

- Electronics

- Industrial equipment

- Furniture

- Glassware

Double wall boxes are often used in industries where durability and strength are a top priority. They help reduce the risk of damage during transport.

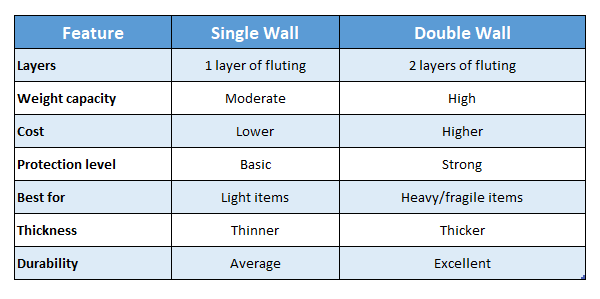

Key Differences Between Single Wall and Double Wall Boxes

Which Box Should You Choose?

This really depends on what you are using the box for. Let’s look at a few scenarios:

1. Shipping Small Retail Products

If you are running an online store and you ship clothes, books, or toys, single wall boxes will usually be enough. They are strong enough for day-to-day shipping and more cost-effective. Using double wall boxes here may increase your shipping cost without adding much benefit.

2. Sending Fragile or Heavy Items

If you are shipping something fragile like a ceramic vase or something heavy like a power tool, double wall boxes are a safer choice. They provide better shock absorption and can handle the extra weight.

3. Long-Distance or International Shipping

The longer the travel, the higher the risk of rough handling. Double wall boxes hold up better over time and under stress. If the box is going through several warehouses and transportation hubs, double wall protection is recommended.

4. Storage for Long Periods

If you need to store products in a warehouse for months or years, double wall boxes are less likely to get crushed or lose shape. They are also better for stacking.

5. Environmental Impact

Both single and double wall boxes are recyclable. However, because single wall boxes use less material, they may have a smaller environmental footprint if you’re only packaging light goods.

Cost Considerations

Double wall boxes usually cost more than single wall ones. This is because they use more material and are heavier. However, if the box prevents damage and avoids returns or replacements, it may save money in the long run.

If your product is expensive or fragile, it’s often smarter to invest a little more in a stronger box rather than risk the item arriving broken.

Strength Ratings (Bursting and Edge Crush Tests)

Corrugated boxes are often rated for strength using two main tests:

- Bursting strength (measured in pounds per square inch) – Tells how much pressure the box can take before it bursts.

- Edge Crush Test (ECT) – Measures how much weight a box can handle when stacked.

Double wall boxes will always score higher on these tests than single wall ones. If you are working with a supplier, you can ask them for the ECT or burst rating to understand how strong the box really is.

Final Thoughts: Which Is Better?

There is no one size fits all answer. Each type of box has its own benefits. Here is a simple way to decide:

- Choose single wall if your item is light, non-fragile, or not being shipped very far.

- Choose double wall if your item is heavy, breakable, or going through long or rough shipping routes.

For most online stores and day-to-day packaging needs, single wall boxes will do the job just fine. But for industrial use or fragile shipments, double wall boxes offer more peace of mind.

Conclusion

Understanding the difference between single wall and double wall corrugated boxes can help you make smarter packaging decisions. Whether you are a small business owner, warehouse manager, or just someone mailing a package, choosing the right box can prevent damage, save money, and ensure your items arrive safely.

Before making a choice, think about what you are shipping, how far it needs to travel, and how much protection it really needs. Sometimes, a little extra strength is worth the cost. Other times, simple and affordable is the way to go.

Always remember: the right box can make a big difference.